SKA Milestone Displays China's Scientific Dedication

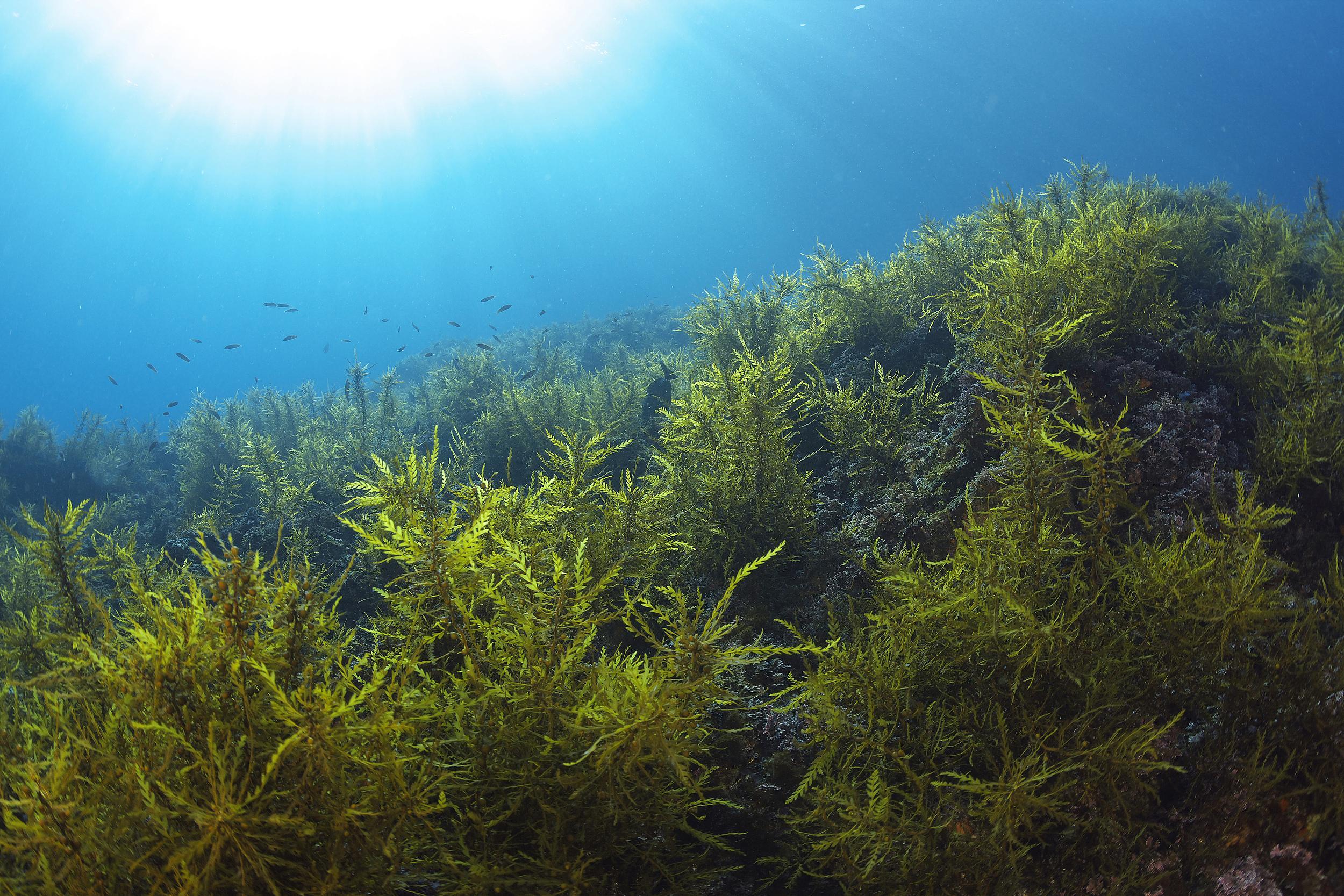

The first mid-frequency dish antenna designed for the Square Kilometer Array (SKA) radio telescope began assembly.?(Photo?taken?by?LIN?Yuchen)

By?LIN?Yuchen

The first mid-frequency dish antenna designed for the Square Kilometer Array (SKA) radio telescope began assembly in Shijiazhuang, north China's Hebei province, on September 20.

This is also the first of the 64 mid-frequency dish antennas China will contribute to the SKA, based on an agreement reached in December 2022 between the Ministry of Science and Technology and the Square Kilometer Array Observatory (SKAO). This work was recognized by SKAO. Recognizing China's efforts, William Garnier, director of communication at SKAO, said that from day one, the country has been a strong proponent of the SKA project.

Construction milestone

The 54th Research Institute of China Electronics Technology Group Corporation (abbreviated as CETC54) is responsible for producing all 64 antennas. The success of the first SKA mid-frequency dish antenna marks a milestone in the SKA construction phase.

The remaining mid-frequency dish antennas can now begin production and will eventually be delivered to South Africa over time, where they will be installed to prepare for the full operation of SKA in early 2027.

The SKA is an international scientific project proposed in the early 1990s. It is the largest synthetic aperture radio telescope ever built, and is a multinational co-funded international scientific project.

Astronomers and engineers from hundreds of universities and research institutions in around 20 countries are involved in the project. The telescope is so named because the total receiving area of the array of radio telescopes is one square kilometer, equivalent to around 140 football fields.

Extreme precision in installation

Aiming for exploring a wider universe, including searching for more galaxies and new cradles, SKA has demanding technical requirements in its antennas, most notably high sensitivity and direction accuracy.

"We have carried out research on key technologies, such as control system design, dynamic simulation, calibration, debugging, test methods and test verification, and completed the design, processing and integration of the control system with high electromagnetic compatibility," Du Biao, chief designer of SKA mid-frequency dish antenna at CETC54, told Science and Technology Daily. See page 2

The main reflecting dish of the entire antenna is a hexagonal space frame structure, consisting of 66 aluminum alloy triangular panels with different curvatures.

These 66 panels have different curvatures, so 66 special molds need to be made separately. In order to ensure the precision requirements, the design team needed to make the panels fit the molds as closely as possible during forming. Designing an effective forming process alone took more than three months, according to the institute.

"The precision of our panel reaches 0.03-0.1 millimeters, which means the precision of the surface shape is better than one hundred microns. It is less than the thickness of two hair strands and represents the highest level of panel design and manufacturing in China." said Yang Jinrong, the project designer of the SKA mid-frequency dish antenna structure.

Behind the high precision requirement is the extreme precision of each installation link. The back frame of mid-frequency dish antenna uses a space frame structure, making the overall weight light. According to CETC54, the back frame is installed by connecting a bolt ball to a rod screw, and there are more than 100 bolt balls and 300 rods screws on each side of the antenna.

What poses challenges in this installation process is that the number of screw holes on the many bolt balls is different, and the angle of each screw hole on each bolt ball is also unique. An error of even the size of a small grain of rice would make it impossible to install.

According to CETC54, in order to quickly and accurately complete the installation and disassembly, the craftsmen conducted dozens of tests, constructed four calculation models, and repeatedly studied the assembly process. They now have fully mastered the best installation method after more than two months of dedicated work.

"Obviously the government came onboard. We have seen a continuous and strong determination from the Chinese government. And a very good example of this is the FAST telescope. The FAST telescope is built here in China, which is one of the path finders of the SKA. FAST is already in operation and is already delivering fantastic scientific insights, which really paves the way for the future of the SKA," said Garnier.