The Secret of Casting Bronze

Siyang Fangzun, the four-goat square zun vessel dating to the Shang Dynasty,is one of the most precious pieces of archaic bronzework excavated in China.(PHOTO: VCG)

By?BI?Weizi

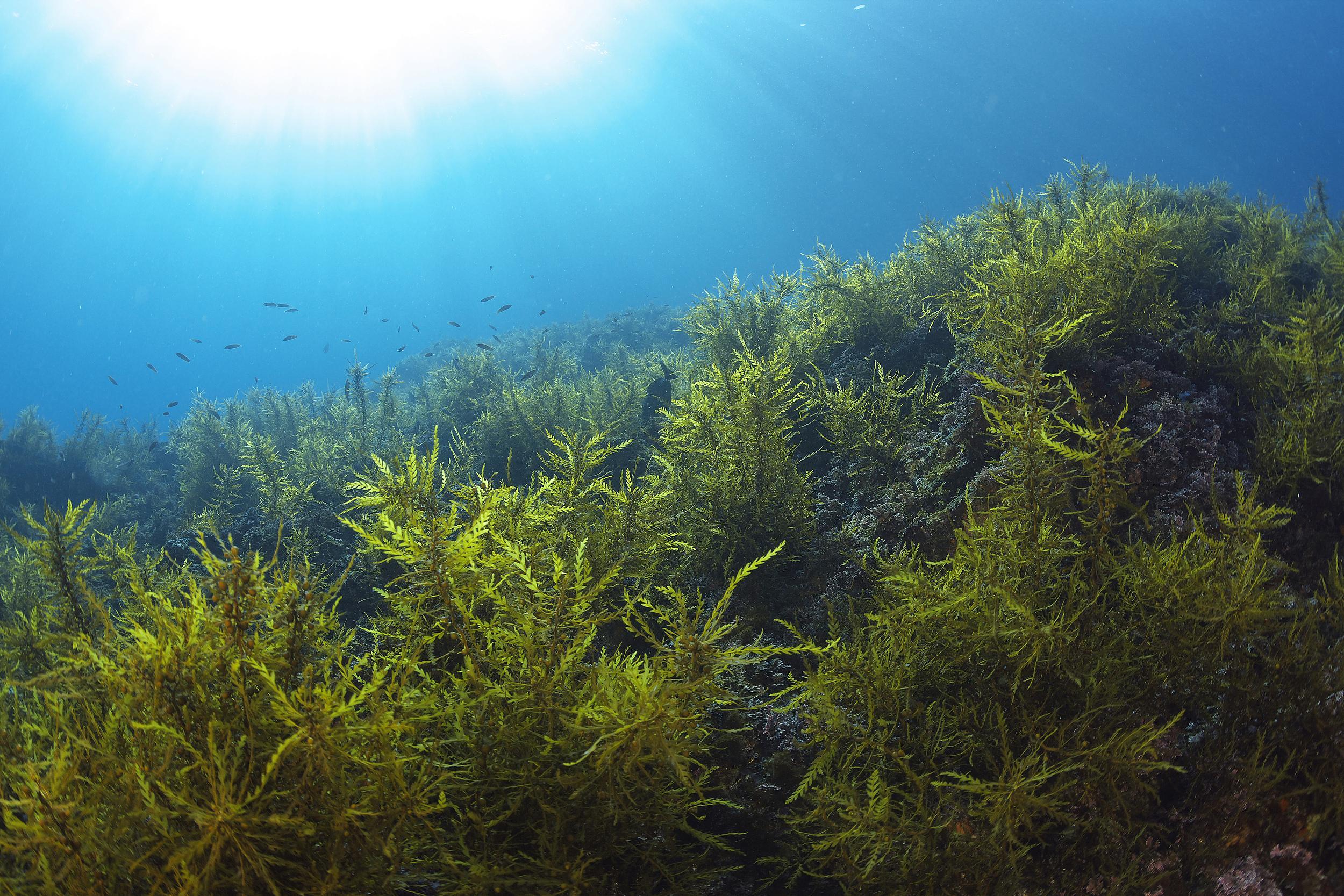

China has a rich history of over 5,000 years of artistic advancement and is the birthplace of one of the world's oldest civilizations. An important part of this advancement is that by 1100 BC, the Chinese had achieved a high level of artistic and technical excellence in bronze casting.

The bronze alloys of copper, tin and lead are inherently difficult to work and shape with a hammer, a technique most commonly used by ancient Europeans and Middle Easterners. However, by the end of the Neolithic period, the Chinese had already demonstrated technical proficiency with hard, thin-walled ceramics, and were able to use these skills to develop a most unusual method of casting, called piece mold casting.

In piece mold casting, a model of the object to be cast is made and a clay mold is made on top of the model. The clay mold is then cut into sections to separate it from the model, and these sections are reassembled after firing to form the mold for casting. If the object to be cast is a vessel, a core must be placed inside the mold to create a cavity for the vessel.

Piece mold casting was probably the only method used in China until at least the end of the Shang Dynasty (1600-1046BC). One of its distinct advantages was that decorative designs could be engraved or stamped directly onto the inner surface of the mold, prior to firing. This technique allowed bronze workers to achieve a high degree of definition and clarity in even the most complex designs.

Today, early Chinese bronzes are renowned for their enduring beauty, but they also offer insight into the culture in which they developed, as well as more modern objects. Their ornate and utilitarian character clearly reflects the quality of Chinese metalworking over thousands of years.